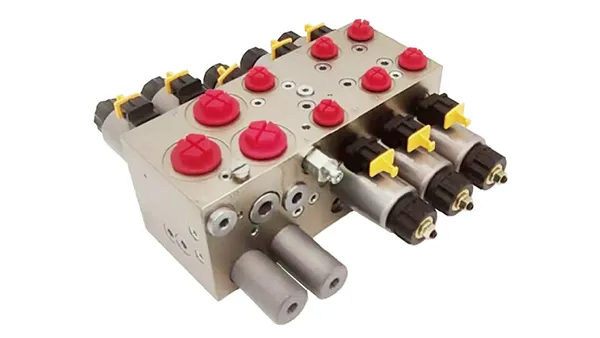

Meet Your Hydraulic Valve Needs

Yuethai is a specialized manufacturer of compact hydraulic system solutions for off-highway machinery, serving global OEMs in construction, agriculture, and material handling sectors.

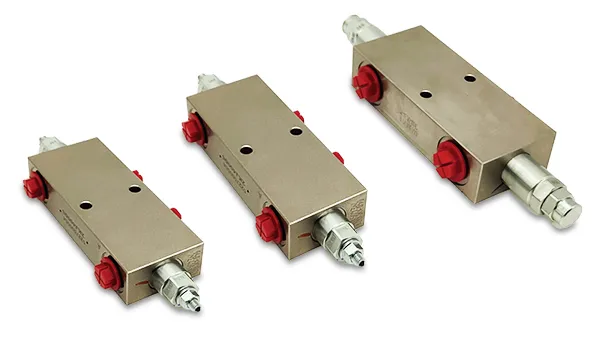

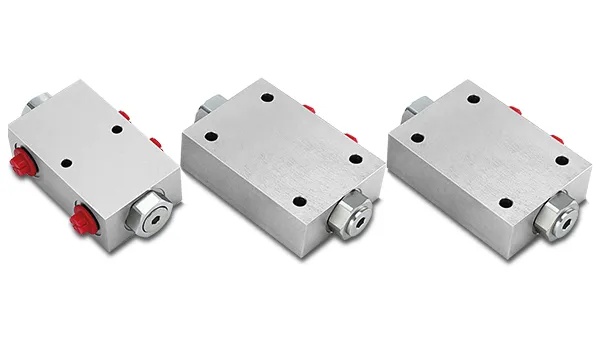

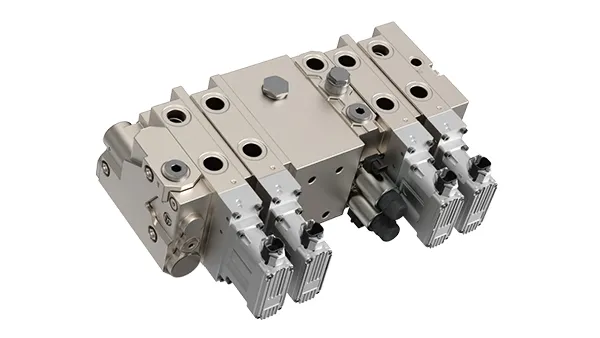

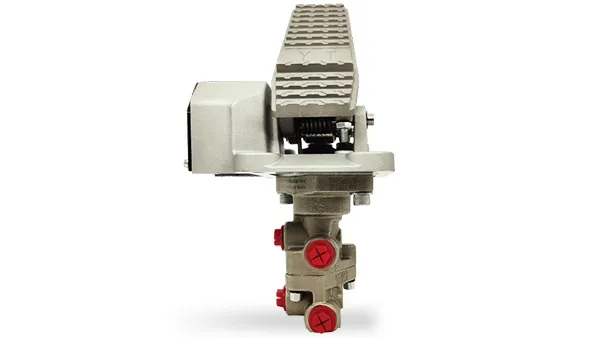

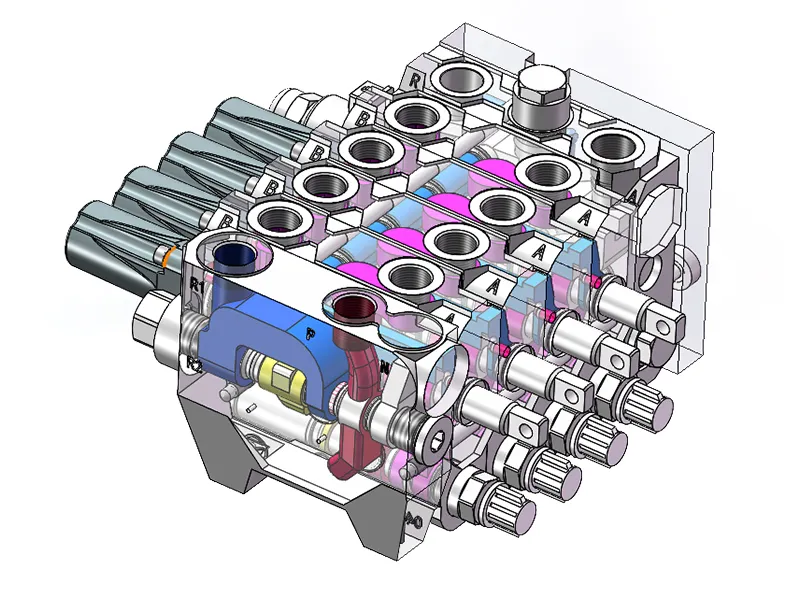

With over 18 years of industry expertise, we design and manufacture a comprehensive range of hydraulic valves and integrated systems covering pilot control, brake control, motion and load control, transmission control, and auxiliary hydraulic functions.

Our core strengths include:

- 90% of key components produced in-house, ensuring full control over quality and consistency

- Inventory of over 200,000 hydraulic components, ready for fast response and order fulfillment

- Flexible production lines with annual capacity exceeding 250,000 units

- Full-process contamination control ensuring NAS 7 cleanliness level in every product