Contact us today - we’re ready to discuss your needs and deliver the right solution.

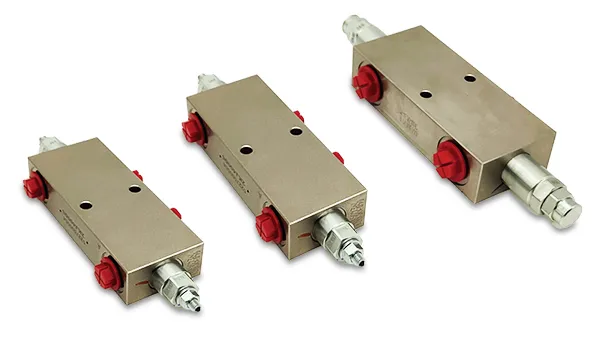

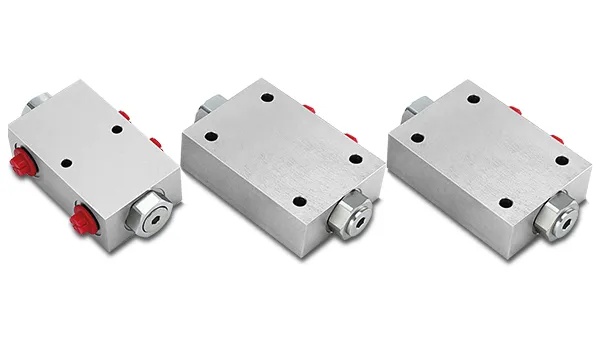

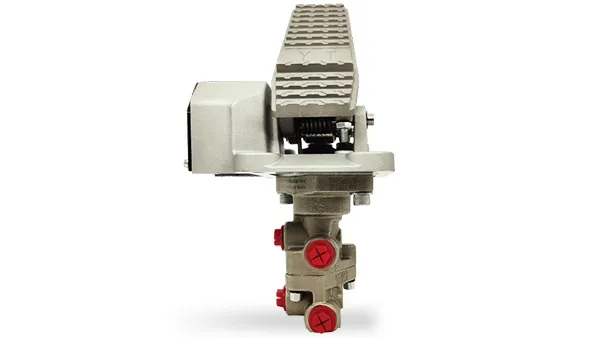

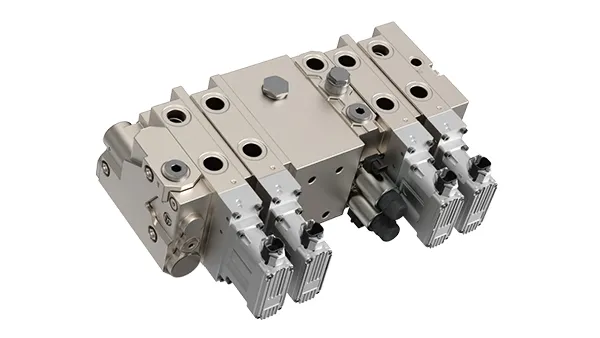

Yuethai operates advanced flexible manufacturing lines designed for both high-volume output and tailored production. All hydraulic system components are delivered with a certified cleanliness level of NAS 7, ensuring reliable performance.

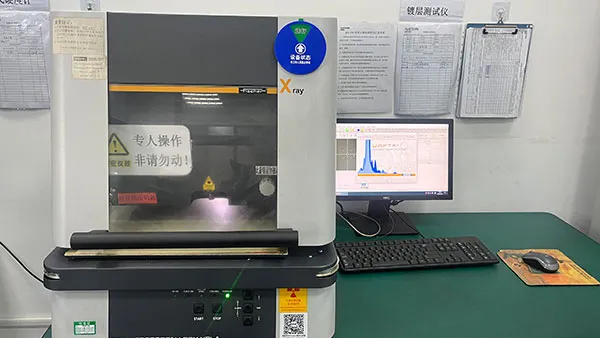

To guarantee product quality and consistency, we apply rigorous testing at 100% of critical quality control points, using advanced inspection equipment and processes. Our internal validation procedures are built to exceed industry standards, reinforcing our commitment to quality, reliability, and customer confidence.

As a precision hydraulic solutions manufacturer, Yuethai Hydraulics places lifecycle quality consistency at the core of our products. Starting from the source selection, we strictly control raw material quality and conduct rigorous testing on key parameters such as hardness and surface roughness. This ensures the consistency and reliability of base materials, providing a solid foundation for precision manufacturing and long-term stable operation.

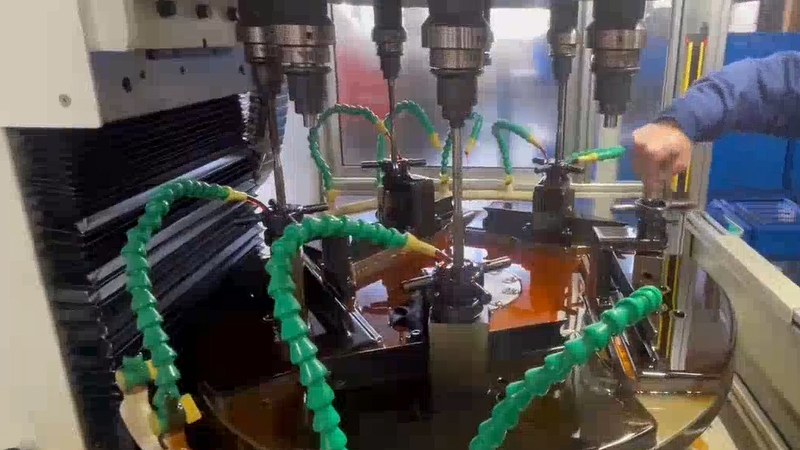

Leveraging a highly automated and advanced manufacturing system, Yuethai Hydraulics has established a stable and efficient production capacity. Multiple vertical and horizontal machining centers operate in coordinated workflows, enabling high-precision and high-efficiency manufacturing. Among them, vertical 4-axis machining allow one-time forming of complex structures with excellent dimensional accuracy. Combined with intelligent flexible production lines, the horizontal machining centers support continuous production of complex, multi-surface, and high-difficulty components, delivering outstanding consistency and productivity.

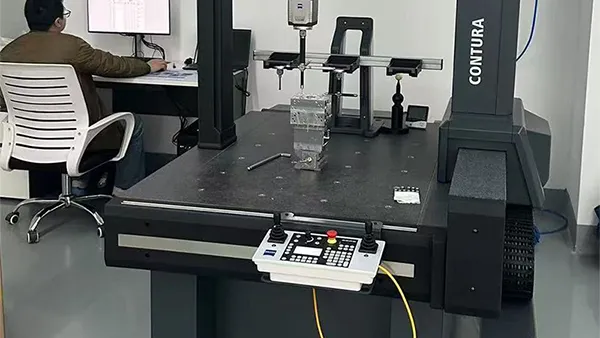

In addition, precision equipment, including honing machines, coordinate measuring machines (CMMs), and ultrasonic cleaning systems, is deployed to ensure controlled quality and stable delivery throughout the entire process, from machining to final shipment.

-

MAZAK Horizontal 4-Axis Machining Center

-

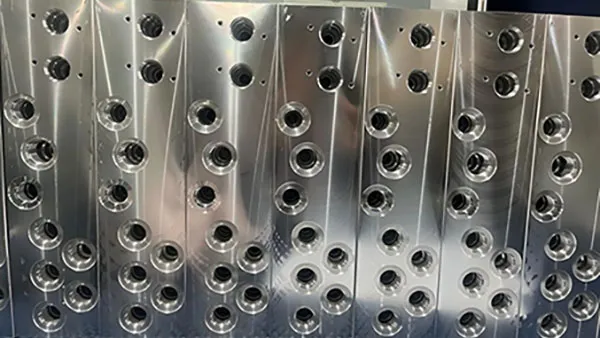

Cleaning & Air Blowing

Component cleaning systems

Water-based ultrasonic cleaning and hydrocarbon ultrasonic cleaning effectively removes contaminants and prepares components for final assembly

Yuethai has established a comprehensive quality management system covering raw materials, production processes, and pre-delivery inspection. Multiple performance tests—including pressure drop, response behavior, pressure characteristics, and proportional control performance—are conducted. These tests are combined with validation under extreme operating conditions, such as service life evaluation, high-pressure resistance, and high-temperature endurance, forming a closed-loop, multi-dimensional quality inspection system. This ensures long-term reliability and stable performance of products during operation.

Precision measurement equipment

Cylindricity testers and coordinate measuring machines (CMMs) are employed to inspect critical dimensions and geometries of each component

Cleanliness inspection equipment

Equipped with gravimetric methods, particle analysis, as well as both offline and online particle counters, enabling effective detection and control of residual particulates and fibers

Automated valve testing stations

Intelligent testing platforms used to verify both the functionality and performance of each valve block

Spare Parts Storage Area

Semi-Finished Product Storage Area

Finished Product Storage Area