Since 2006, Yuethai has specialized in designing and manufacturing tailored hydraulic solutions for mobile equipment OEMs. Serving construction machinery, agricultural machinery, and material handling equipment, we deliver over 500 unique hydraulic solutions every year, with our hydraulic products installed on more than one million machines worldwide.

To make sure every project meets your needs, we work closely with you from concept through to production:

- Understanding and confirming your requirements

- Conducting a detailed technical evaluation

- Providing a preliminary quotation for confirmation

- Project feasibility assessment and approval

- Delivering a tailored hydraulic design proposal

- Finalizing the quotation and project confirmation

- Developing prototypes under a dedicated contract

- Delivering and testing sample units

- Producing small batches for field use

- Full-scale mass production and delivery

Our goal is to help OEM partners gain a competitive edge. With decades of engineering expertise and continuous innovation, we deliver system-level, customized hydraulic solutions across key applications, including:

- Pilot control

- Brake control

- Motion and load control

- Transmission control

- Auxiliary and attachment control

Through continuous innovation and customized system integration, we help our customers improve machine performance, adapt to complex operational needs, and gain long-term competitive advantages in their respective markets.

Our flexible manufacturing system allows us to respond quickly to project requirements while maintaining strict quality standards. By utilizing advanced automation, intelligent production scheduling, and highly integrated processes, we ensure high-precision production and rapid response in order to provide consistent, reliable output.

This capability allows us to efficiently handle small-batch customization as well as large-scale production, ensuring customers receive high-quality hydraulic solutions on time.

We are committed to consistently providing high-quality hydraulic products that perform reliably in demanding environments. We focus on excellence in every step of production: manufacturing, machining, cleaning, assembly, and testing, with 100% inspection at all critical quality points before products leave our facility.

Our automated and flexible production lines minimize the impact of human error, while a comprehensive quality management system ensures product consistency, durability, and long-term reliability. Our strict contamination control processes maintain NAS 7 cleanliness standards, ensuring long-lasting, dependable hydraulic solutions for every customer.

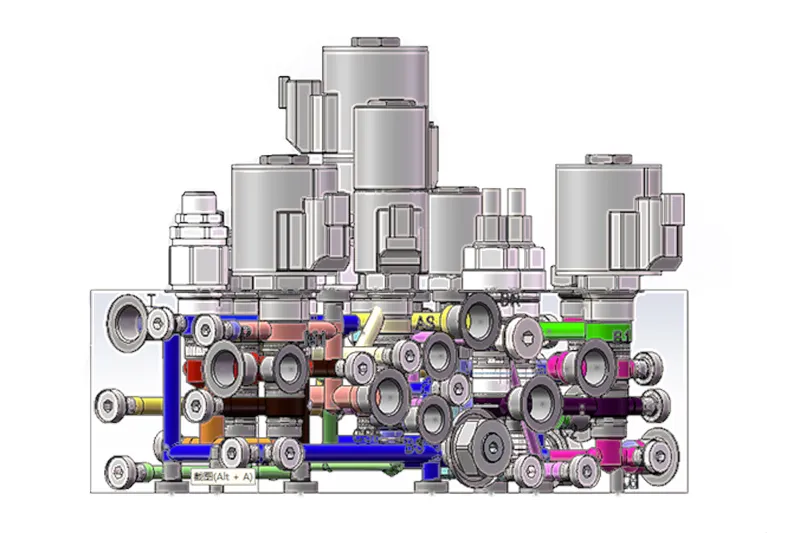

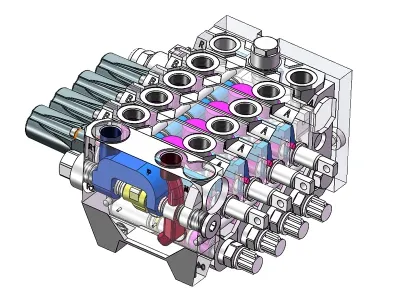

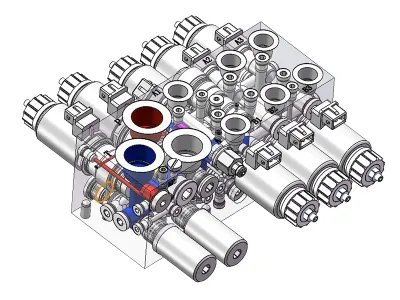

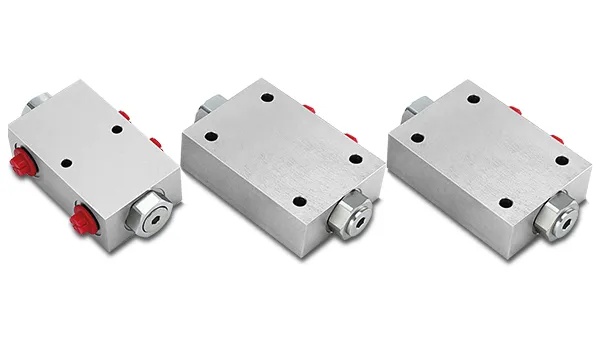

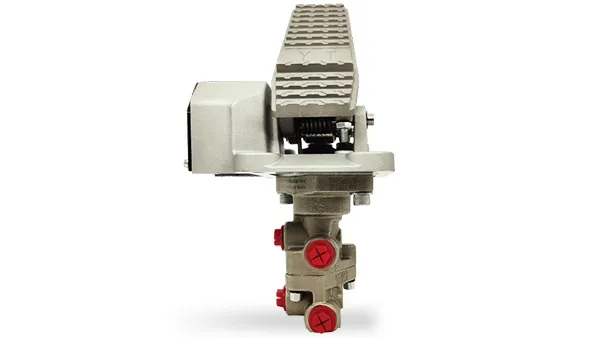

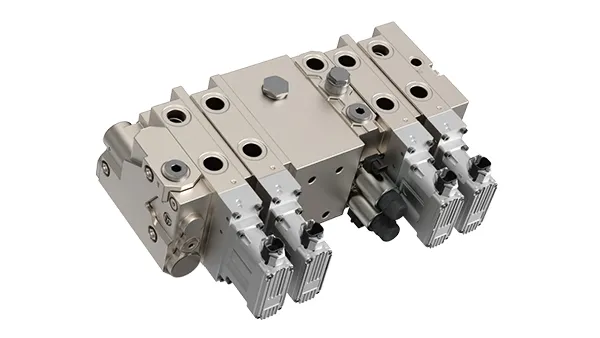

We provide a wide range of hydraulic control units and system modules that can be customized to fit different types of mobile machinery, ensuring each solution meets the specific needs of your application:

- Hydraulic pilot control units

Pilot control valve blocks for large, medium, and small excavators, mini excavators, wheeled excavators, loaders, and backhoe loaders - Hydraulic brake control system units

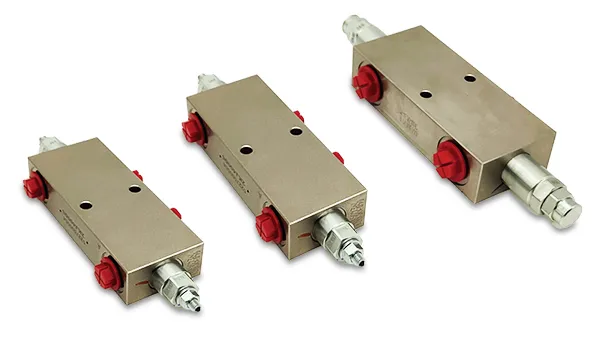

Service brake valves, accumulator charging valves, hydraulic accumulators, brake release valves, and manual emergency brake valves - Motion and load control units

Load-holding valves, pilot-operated check valves, counterbalance valves, and self-leveling valve blocks - Transmission control units

Electro-proportional control valve blocks for tractor power shuttle, power shift, CVT transmission; shuttle shift valve blocks; PTO valve blocks; bulldozer transmission control valve blocks - Auxiliary and attachment control units

Hydraulic shear control valves, electromagnetic valves for grapples, crusher bucket control valves, and quick coupler control valves - Other custom hydraulic systems designed per customer requirements