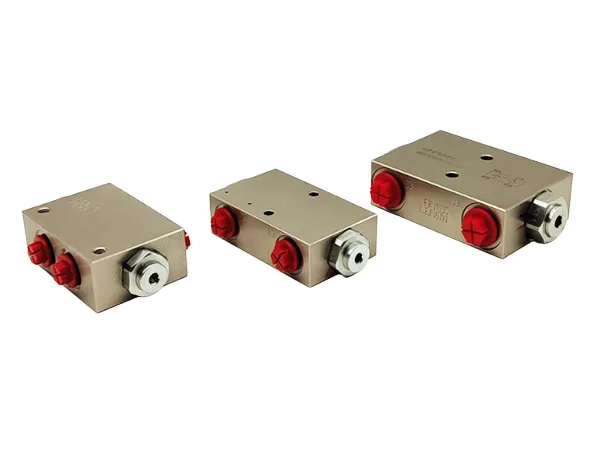

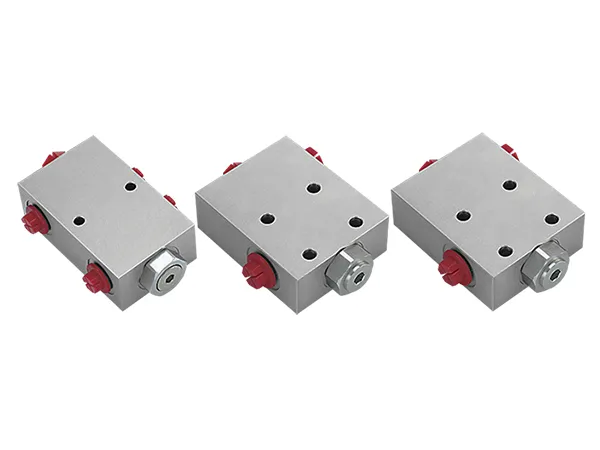

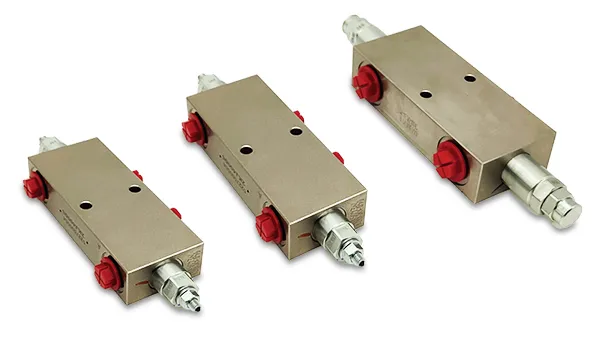

MPCA Single Pilot Operated Check Valve

MPCA Single Pilot Operated Check Valve

- Modular, compact design engineered for safe and reliable load holding in hydraulic systems

- Available in multiple flow capacity options, suitable for diverse installation requirements across various machinery applications

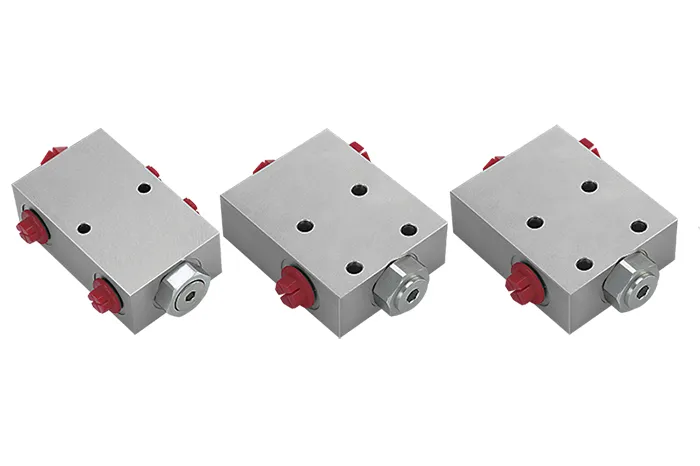

Model Options

| Model | Pressure | Flow |

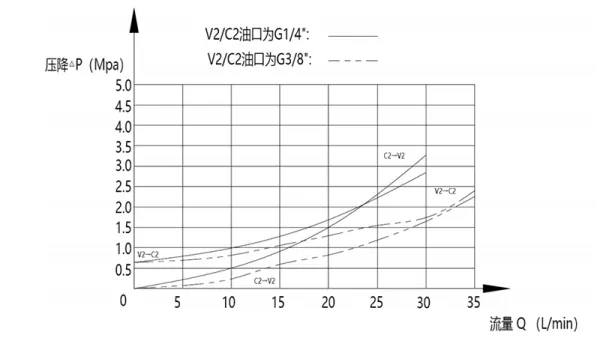

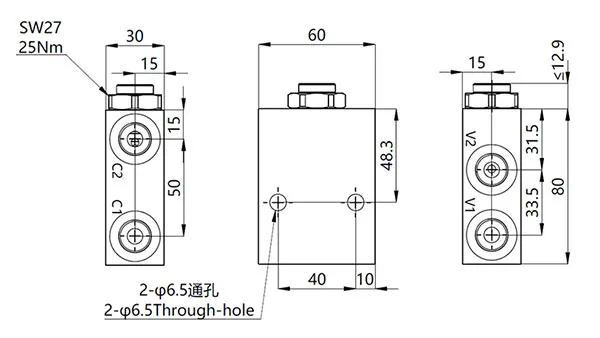

| MPCA-08 Single Pilot Operated Check Valve | 210bar | 30L/min |

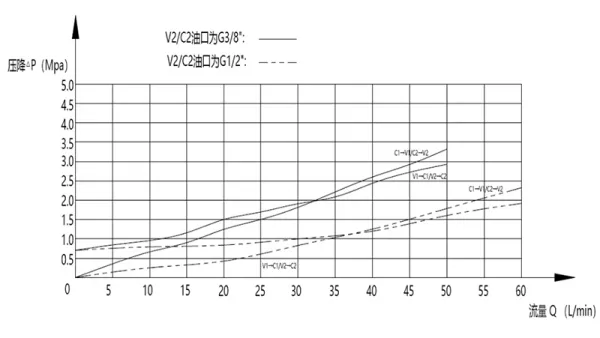

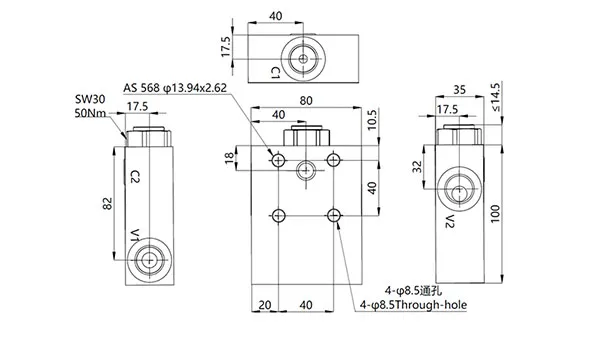

| MPCA-10 Single Pilot Operated Check Valve | 210bar | 60L/min |

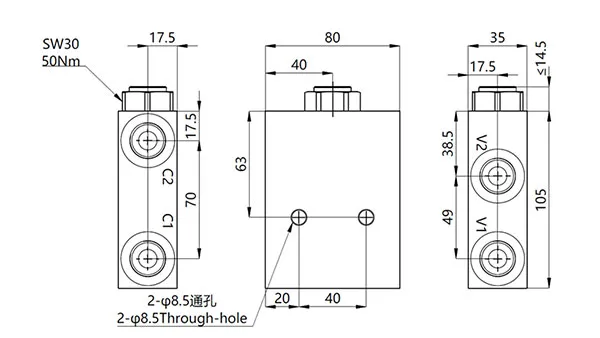

| MPCA-12 Single Pilot Operated Check Valve | 210bar | 100L/min |

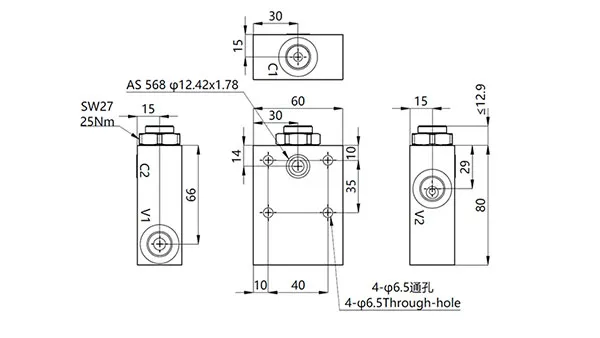

Specifications

| Rated Pressure | 210bar |

| Rated Flow | 30L/min 60L/min 100L/min |

| Fluid Temperature Range | -30℃~100℃ |

| Ambient Temperature Range | -20℃~80℃ |

| Valve Body Material | Aluminum alloy |

| Oil Viscosity Range | ISO 20~400mm²/s |

Performance Curve

Performance Curve

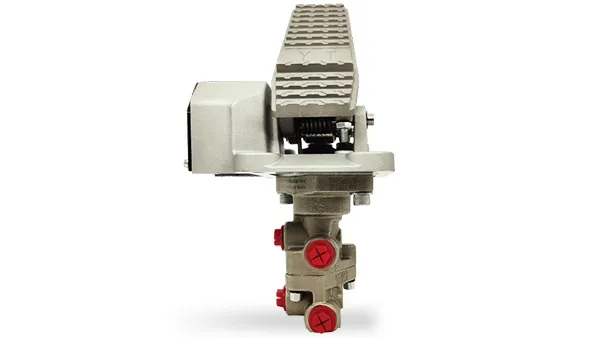

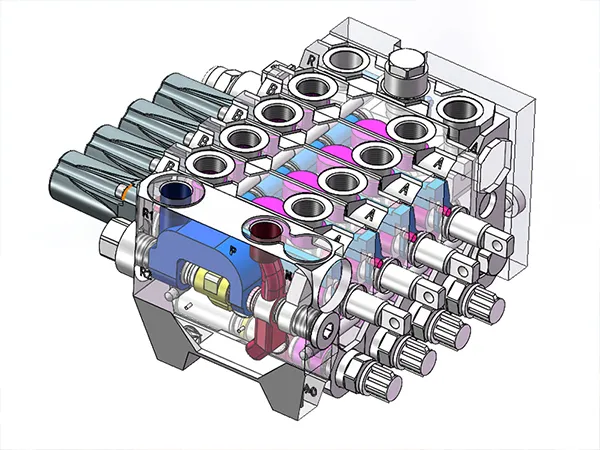

Applications

The single pilot operated check valve (210 bar) is used across a wide range of equipment in construction machinery and material handling applications, that ensures secure cylinder locking and keeps actuator movement steady:

- Excavators: Installed on dozer blades, attachment arms, and other critical sections to lock cylinder positions and move steadily , ensuring operational safety and stability.

- Earthmoving machines: Used on graders, backhoe loaders, and various road construction equipment to prevent hydraulic actuators from unintended movement caused by external forces or system pressure loss.

- Material handling equipment: Ideal for telehandlers, aerial work platforms, and AGV transport vehicles, providing reliable cylinder locking and controlled motion to maintain equipment safety during lifting and handling operations.