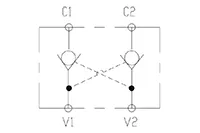

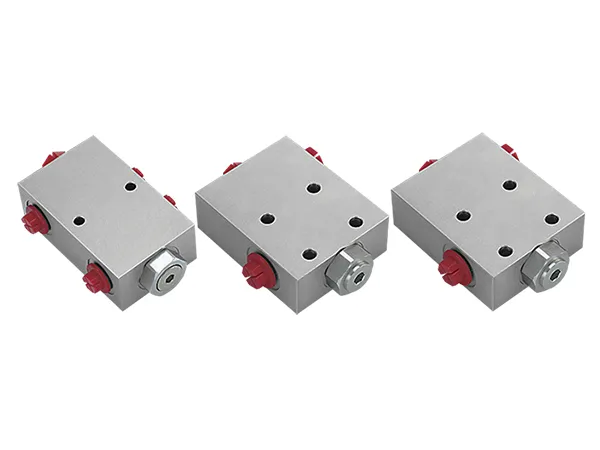

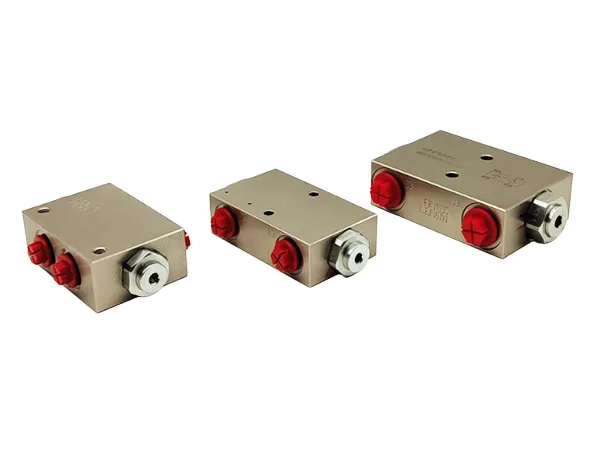

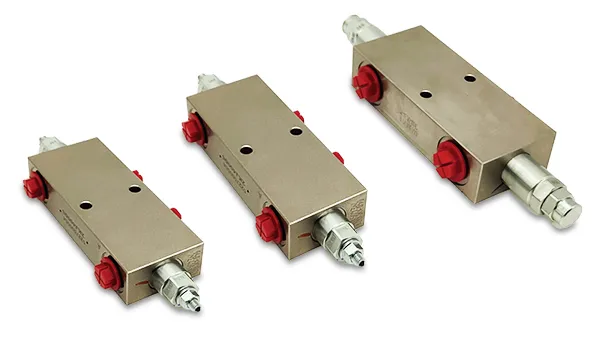

MPCS Dual Pilot Operated Check Valve

MPCS Dual Pilot Operated Check Valve

- Modular, compact design engineered for safe and reliable load holding in hydraulic systems

- Available in multiple flow capacity options, suitable for diverse installation requirements across various machinery applications

Model Options

| Model | Pressure | Flow |

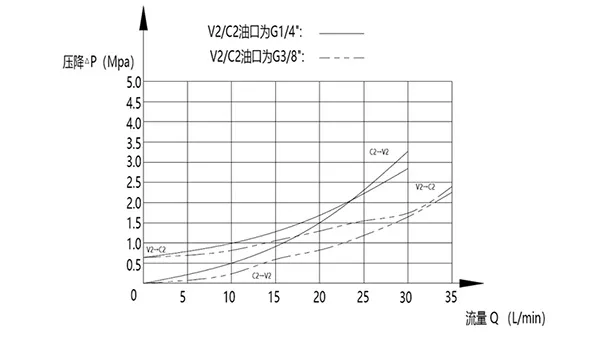

| MPCS-08 Dual Pilot Operated Check Valve | 350bar | 30L/min |

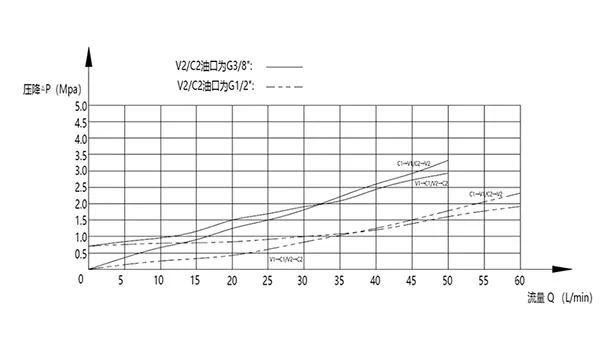

| MPCS-10 Dual Pilot Operated Check Valve | 350bar | 60L/min |

| MPCS-12 Dual Pilot Operated Check Valve | 350bar | 100L/min |

Specifications

| Rated Pressure | 350bar |

| Rated Flow | 30L/min 60L/min 100L/min |

| Fluid Temperature Range | -30℃~100℃ |

| Ambient Temperature Range | -20℃~80℃ |

| Valve Body Material | Steel |

| Oil Viscosity Range | ISO 20~400mm²/s |

Performance Curve

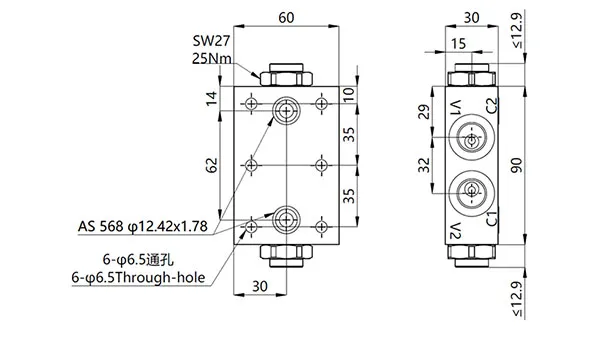

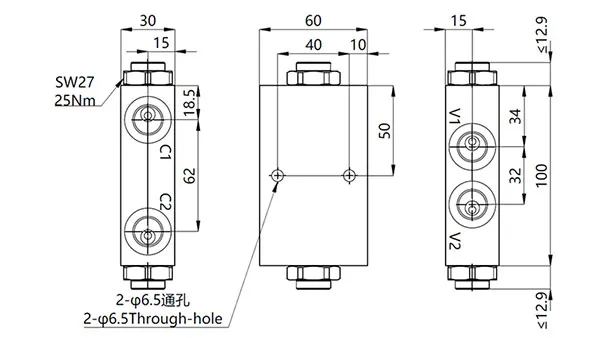

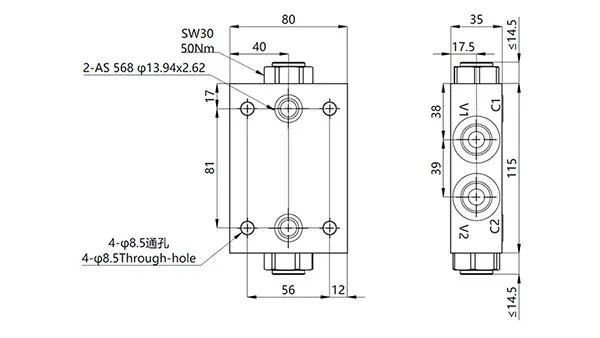

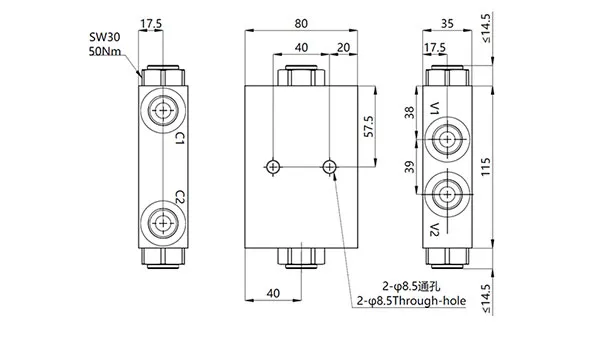

Installation Dimension Drawings

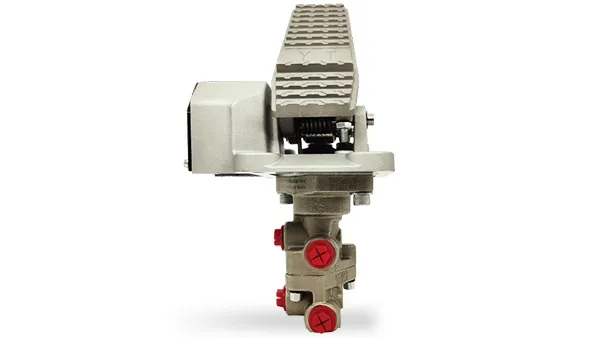

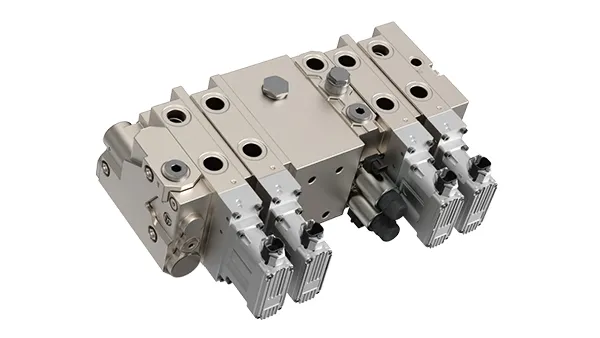

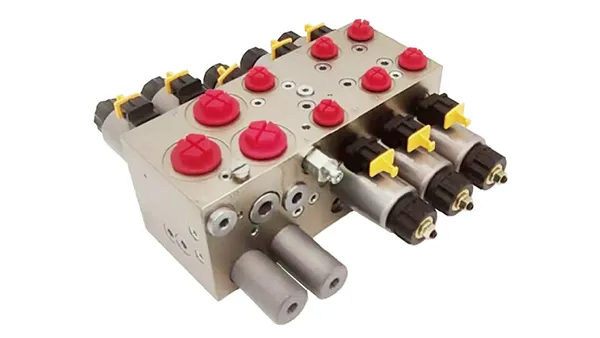

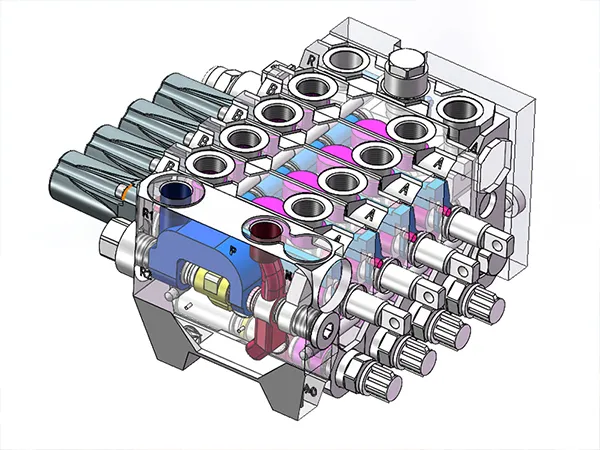

Applications

The dual pilot operated check valve (350 bar) is designed for hydraulic systems that require reliable bi-directional load holding to securely lock cylinders during extension and retraction. It is commonly used in:

- Excavators: Installed on dozer blades, auxiliary arms, and attachments to hold cylinders firmly in place during heavy-duty operations, ensuring safe and steady equipment performance.

- Earthmoving equipment: Applied on graders, backhoe loaders, and road construction machinery to prevent cylinders from unintended movement caused by external forces or system pressure changes, improving on-site stability.

- Material handling machines: Suitable for telehandlers, aerial lifts, and AGV carriers, offering dependable cylinder locking and precise motion control for safer and more consistent lifting and positioning.