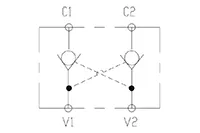

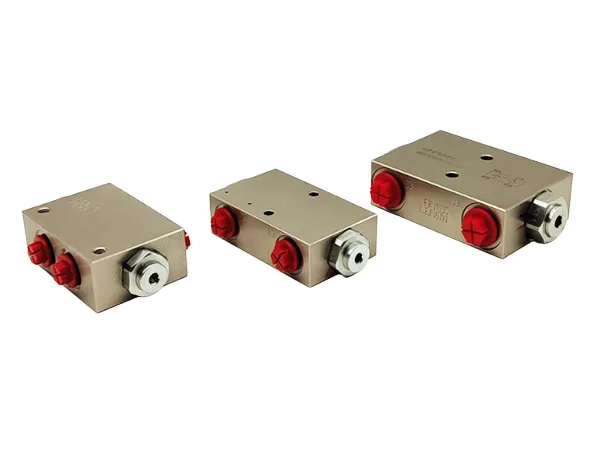

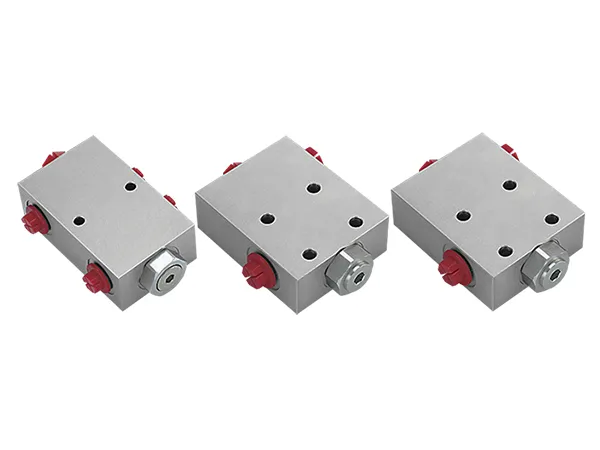

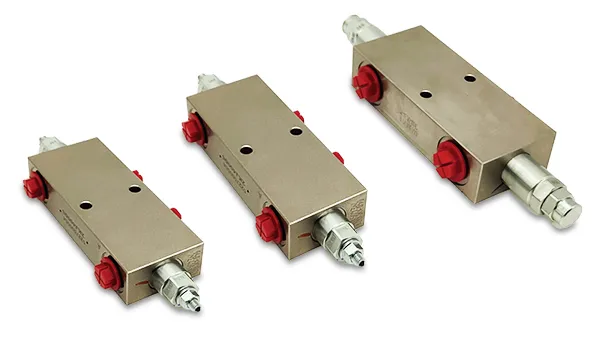

MPCA Dual Pilot Operated Check Valve

MPCA Dual Pilot Operated Check Valve

- Modular, compact design engineered for safe and reliable load holding in hydraulic systems

- Available in multiple flow capacity options, suitable for diverse installation requirements across various machinery applications

Model Options

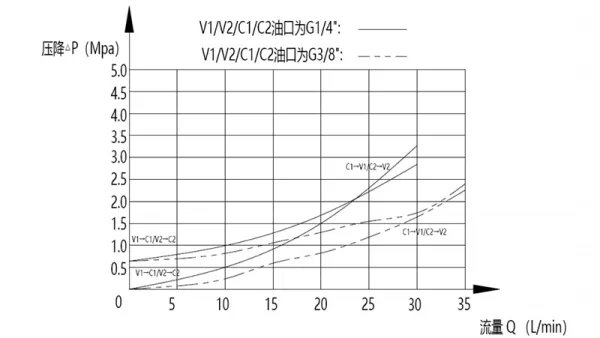

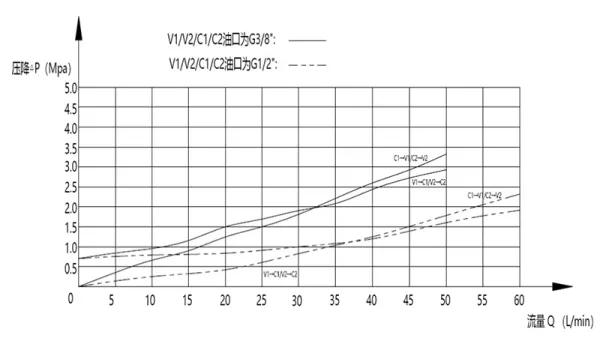

| Model | Pressure | Flow |

| MPCA-08 Dual Pilot Operated Check Valve | 210bar | 30L/min |

| MPCA-10 Dual Pilot Operated Check Valve | 210bar | 60L/min |

| MPCA-12 Dual Pilot Operated Check Valve | 210bar | 100L/min |

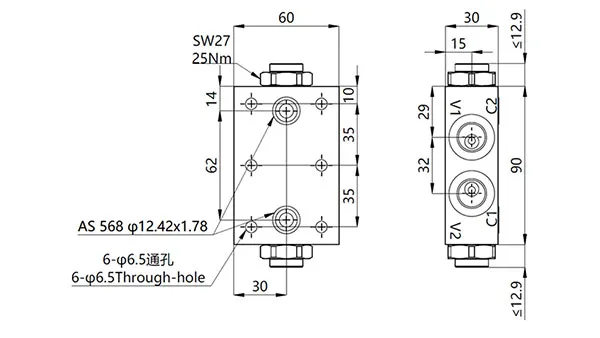

Specifications

| Rated Pressure | 210bar |

| Rated Flow | 30L/min 60L/min 100L/min |

| Fluid Temperature Range | -30℃~100℃ |

| Ambient Temperature Range | -20℃~80℃ |

| Valve Body Material | Aluminum alloy |

| Oil Viscosity Range | ISO 20~400mm²/s |

Performance Curve

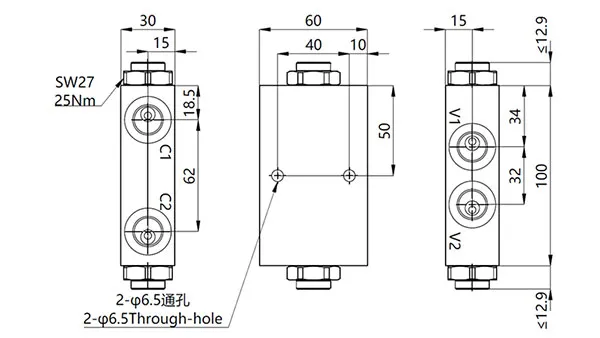

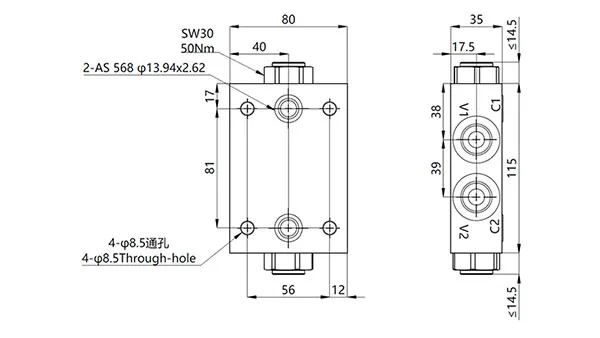

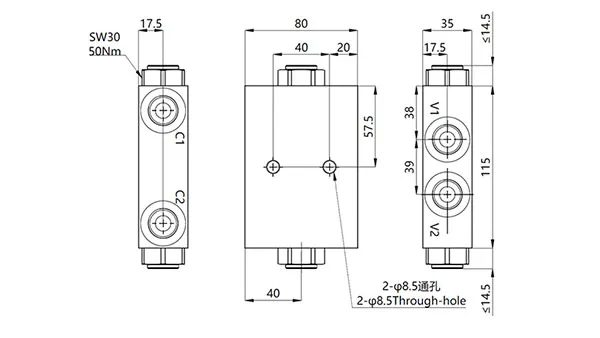

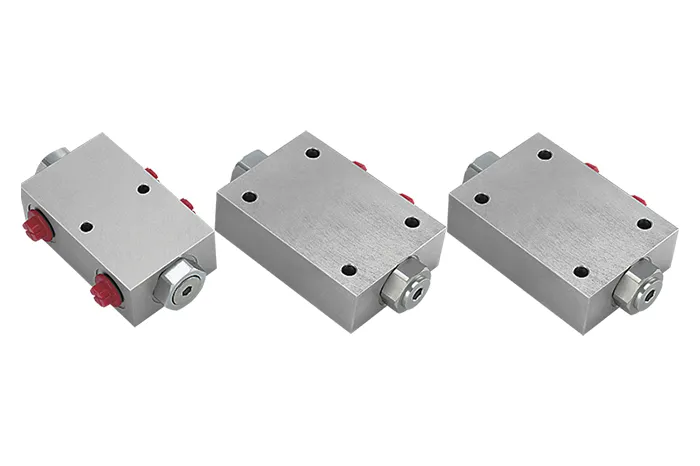

Installation Dimension Drawings

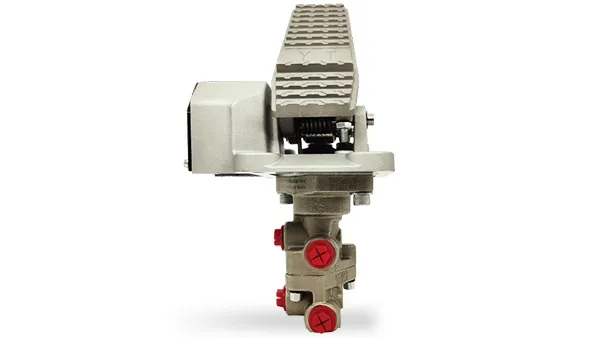

Applications

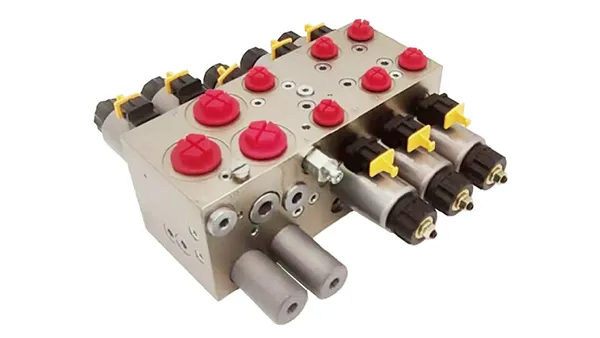

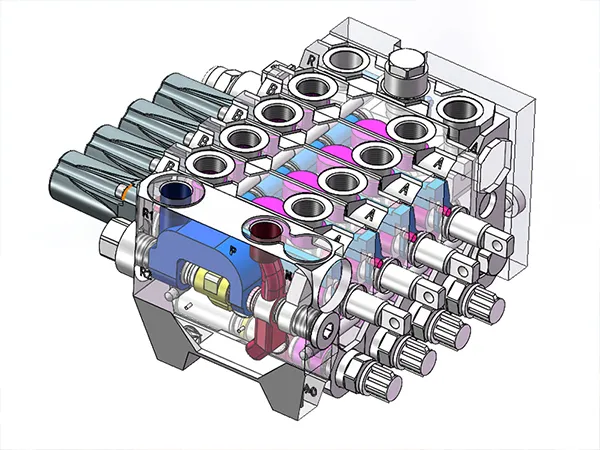

The dual pilot operated check valve (210 bar) is designed for hydraulic systems that require reliable load holding in both directions, making it ideal for cylinders that need to stay securely locked during extension and retraction. It is commonly used in:

- Excavators: Installed on dozer blades, auxiliary arms, and attachments to hold cylinders firmly in place during heavy-duty operations, ensuring safe and steady equipment performance.

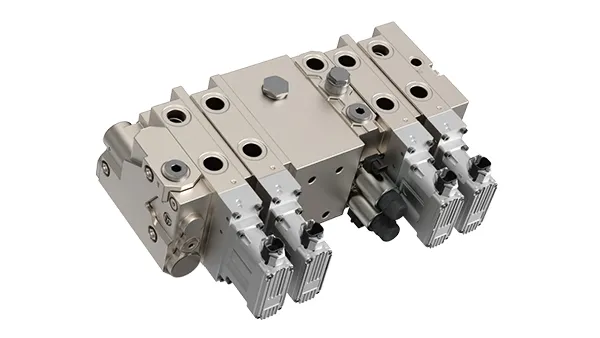

- Earthmoving equipment: Applied on graders, backhoe loaders, and road construction machinery to prevent cylinders from unintended movement caused by external forces or system pressure changes, improving on-site stability.

- Material handling machines: Suitable for telehandlers, aerial lifts, and AGV carriers, offering dependable cylinder locking and precise motion control for safer and more consistent lifting and positioning.